Our Offerings

At BluePhase Cryogenics, we specialize in Deep Dry Cryogenic Treatment (DDCT)— Proven over 20 years at -190°C, our process significantly enhances the performance, durability, and dimensional stability of metal components. Whether it’s cutting tools, automotive parts, dies & punches, bearings, or precision components, our cryogenic solutions are tailored to deliver tangible improvements in wear resistance, fatigue life, and overall efficiency across a wide range of industrial applications. All plants are designed, developed, and manufactured by us using our proprietary, fully indigenized technology, ensuring reliability, consistency, and ease of integration into your workflow.

We offer two core solutions: Job Work Services for industries looking to upgrade the performance of their existing components, and Cryogenic Plants for organizations that prefer in-house cryogenic capabilities:

- Job Work Services – A cost-effective, plug & play solution for Cryogenic Treatment of existing components. Ideal for cutting tools, dies & moulds, bearings, and engineering parts, this service enhances performance and life without the need for capital investment.

- Cryogenic Plants – A turnkey, in-house Cryogenic Solution built on globally competitive, proprietary technology. Customized to your needs, each plant features modular scalability, automated process control, and operation at -190°C. We also provide custom fixturing to ensure uniform, high-precision treatment across varied components. With comprehensive training, technical support, and seamless workflow integration, it enables full process ownership and long-term reliability.

From design to delivery, everything at BluePhase is handled in-house—giving us full control over process precision and quality assurance. With years of experience and a strong foundation in engineering, we support our clients not just with advanced treatment solutions, but also with technical insights, trial support, and training to help them maximize the impact of cryogenics on their operations.

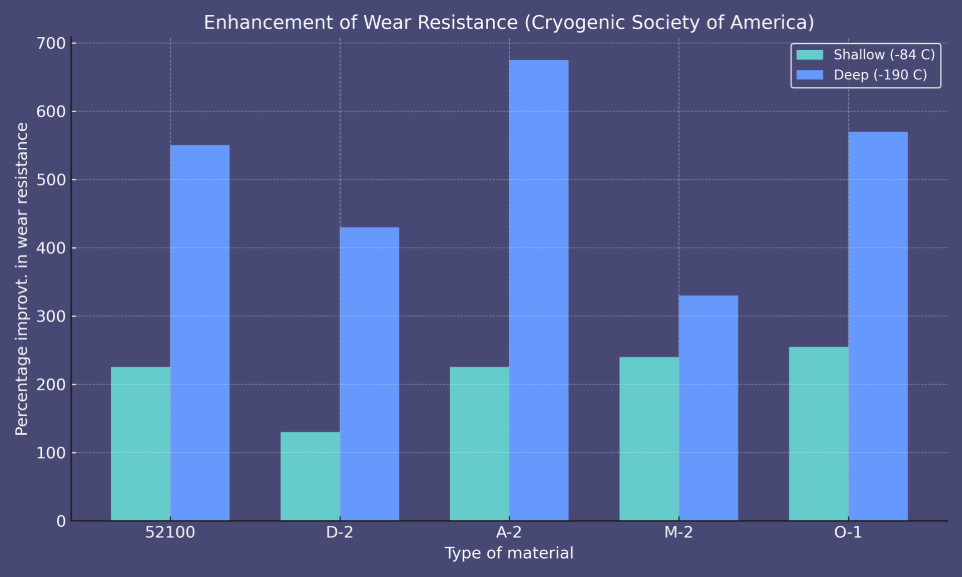

Deep Dry Cryogenic Treatment (DDCT) is not limited to a niche set of steels—it benefits a sweeping range of ferrous and non-ferrous alloys by transforming residual austenite, stabilising carbides, and relieving internal stress. In our own practice we routinely process everything from cutting-tool steels to aluminium engine blocks, improving wear life, dimensional stability and fatigue resistance across vastly different operating environments.

Materials commonly treated with DDCT include:

- Bearing & carbon steels: 52100 (shown in the graph), 1045, 4140/42CrMo4, 8620

- Cold- & oil-work tool steels: D-series (D2, D3), O-series (O1)

- Air-hardening tool steels: A-series (A2, A6)

- High-speed & hot-work steels: M-series (M2 in the graph, plus M35, M42), H13, H11

- Stainless & martensitic grades: 410, 420, 440C, 17-4 PH

- Cast irons & ductile irons: grey, ADI, Ni-resist

- Cemented carbides & powdered-metal tools

- Aluminium & copper alloys: 2xxx–7xxx Al wrought/cast, Cu-Cr-Zr electrodes

- Nickel- and cobalt-based superalloys: Inconel, Hastelloy, Stellite valve seats

- Titanium & Ti-6Al-4V, plus critical additively-manufactured (3-D printed) metal parts

Core Applications for Cryogenics (non-exhaustive)

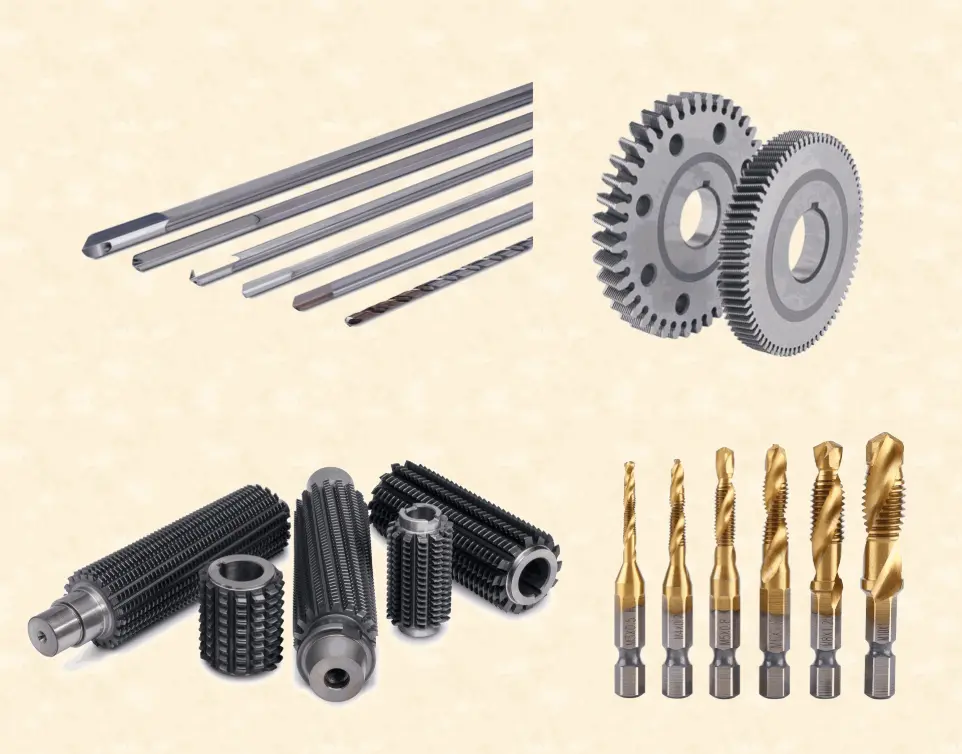

Cutting Tools

- HSS and carbide tools (drills, mills, hobs, inserts, etc.)

- Slot cutters and gear cutters

- Threading tools and broaches

- Gun drill & centre drill

Forming & Stamping Tooling

- Press dies (blanking, punching, trimming, forming)

- Injection moulds and extrusion dies

- Fixtures, punches, and jigs

Automotive & Off-Highway Components

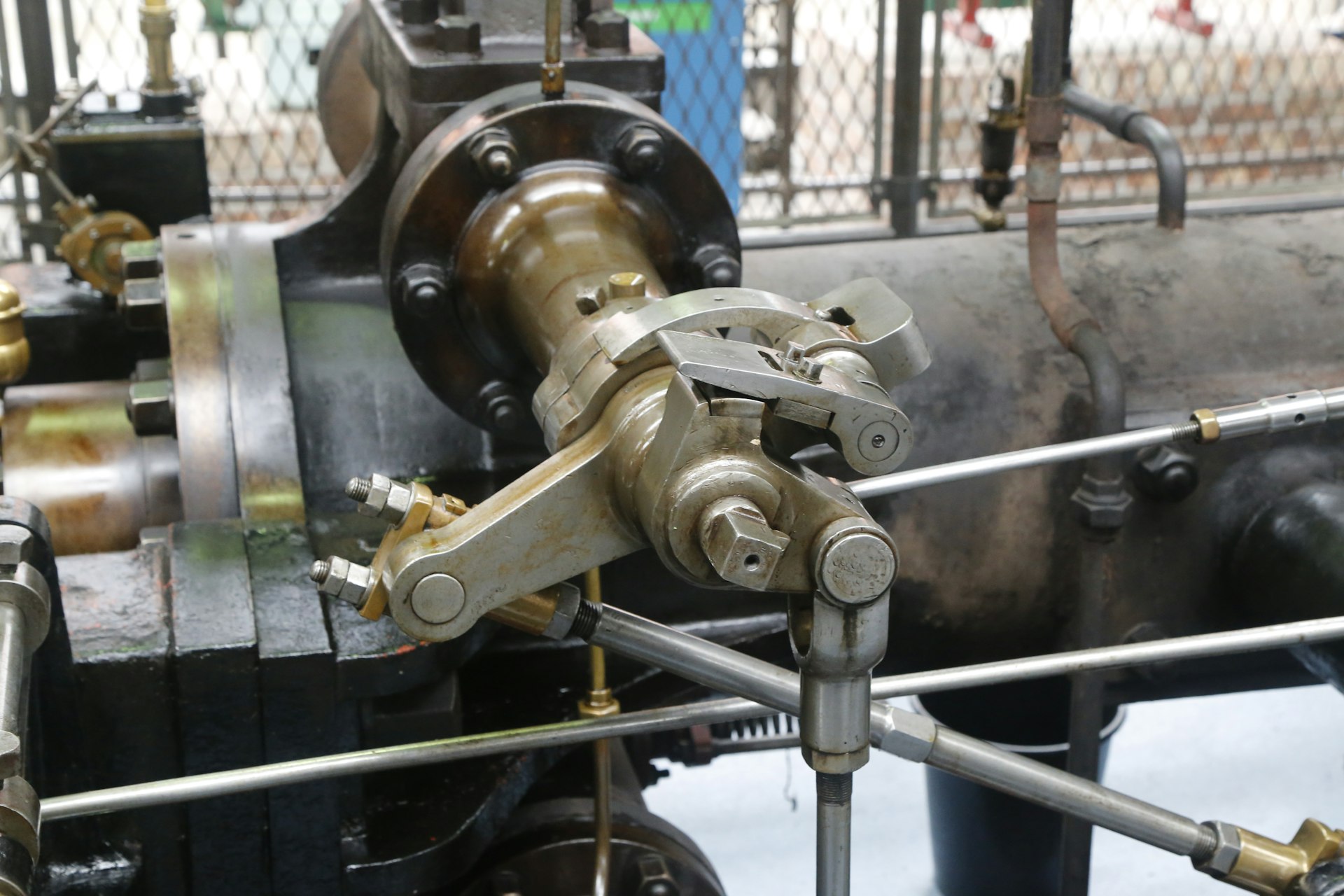

- Gears, crankshafts, spools, and bushings

- Hydraulic lift components (bush & spool assemblies)

- Valves, fuel system parts, transmission components

- Brake rotors, clutch plates, spark plugs, suspension pins/arms

Fluid & Motion Systems

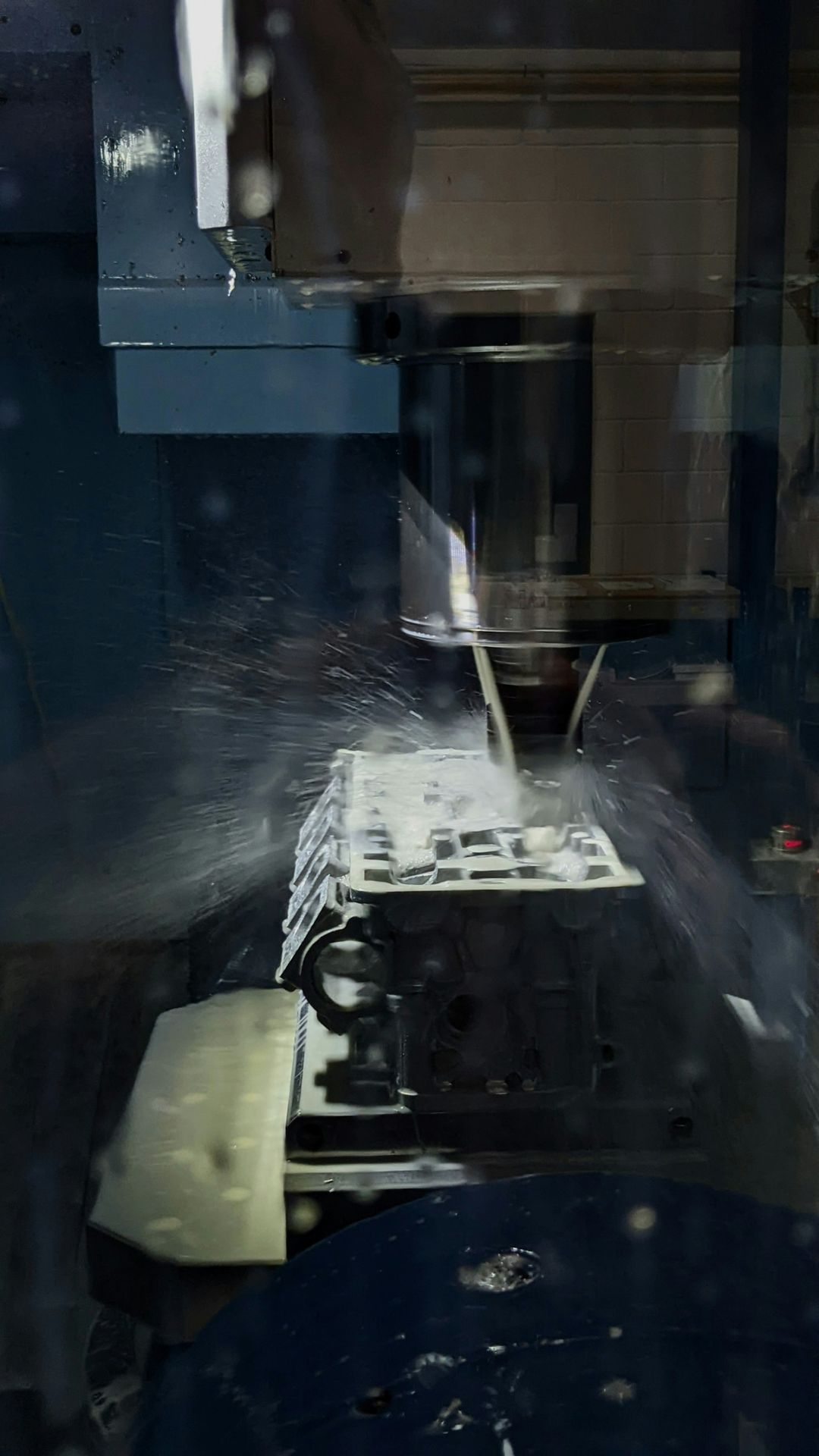

- Hydraulic and pneumatic system parts

- Pump internals, precision cylinders, pistons

- Wear-critical components in valves and regulators

- Seals, plungers, pump rotors/stators, turbocharger bushings

High-Performance & Specialized Applications

- Aerospace & defence components (gun barrels, landing gear, actuators)

- 3D-printed metal parts requiring stress relief

- Seam welding electrodes (e.g., Cu-Cr-Zr)

Precision Electronics & Audio

- Audio equipment parts (diaphragms, signal connectors)

- High-precision electronic tooling

- EMI shielding components & vibration-sensitive elements

Unlock more life, more precision, less downtime.

Get in touch to explore how cryogenics can work for you