High-Impact Applications of Our Technology

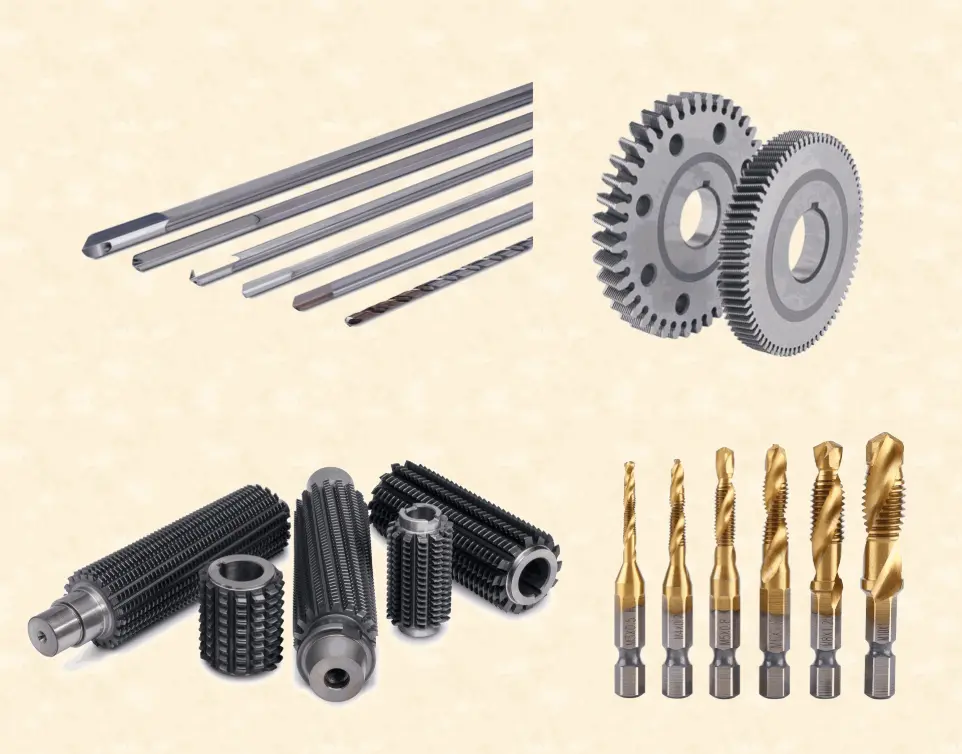

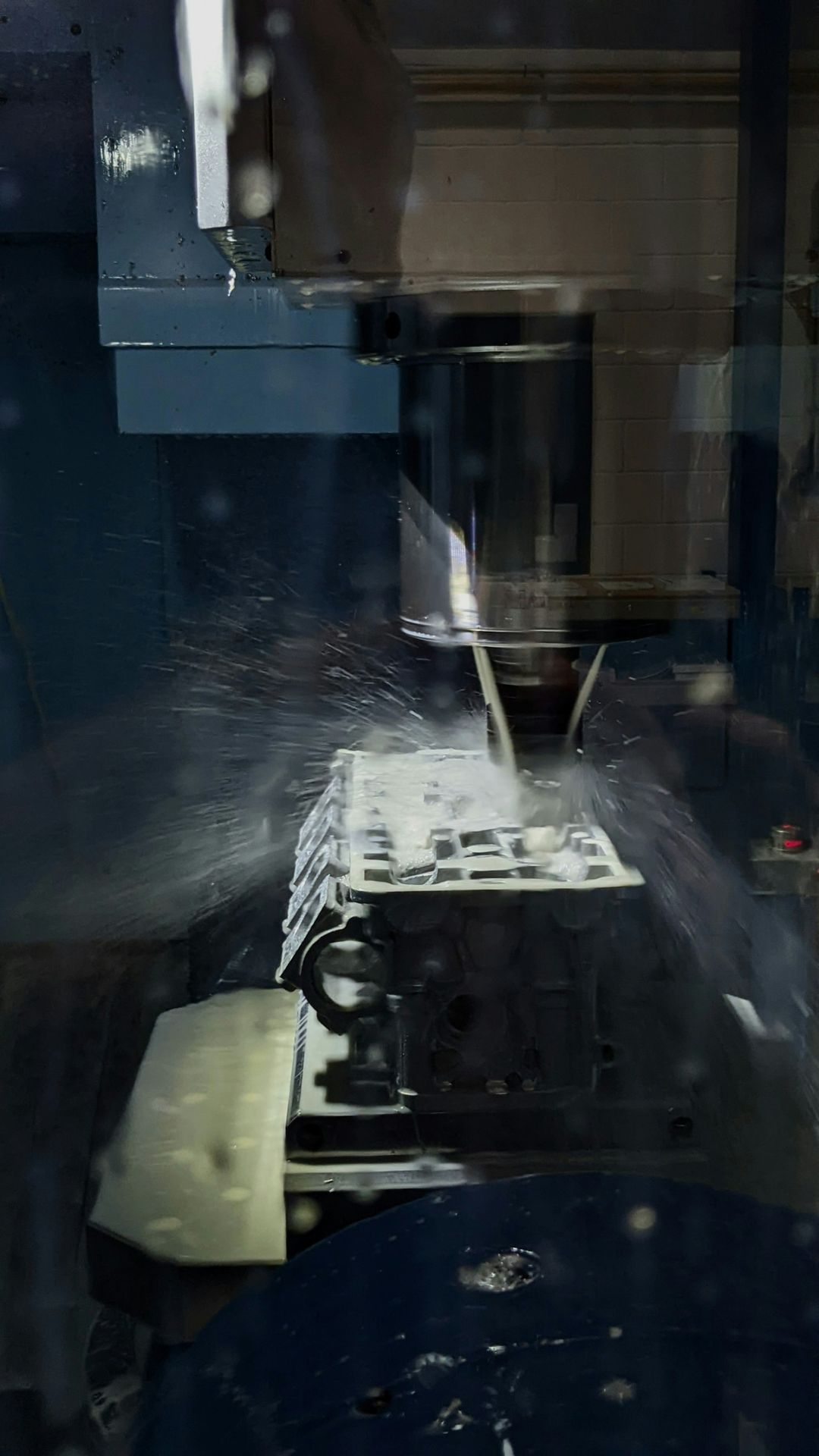

Cutting Tools

- HSS and carbide tools (drills, mills, hobs, inserts, etc.)

- Slot cutters and gear cutters

- Threading tools and broaches

- Gun drill & centre drill

Forming & Stamping Tooling

- Press dies (blanking, punching, trimming, forming)

- Injection moulds and extrusion dies

- Fixtures, punches, and jigs

Automotive & Off-Highway Components

- Gears, crankshafts, spools, and bushings

- Hydraulic lift components (bush & spool assemblies)

- Valves, fuel system parts, transmission components

- Brake rotors, clutch plates, spark plugs, suspension pins/arms

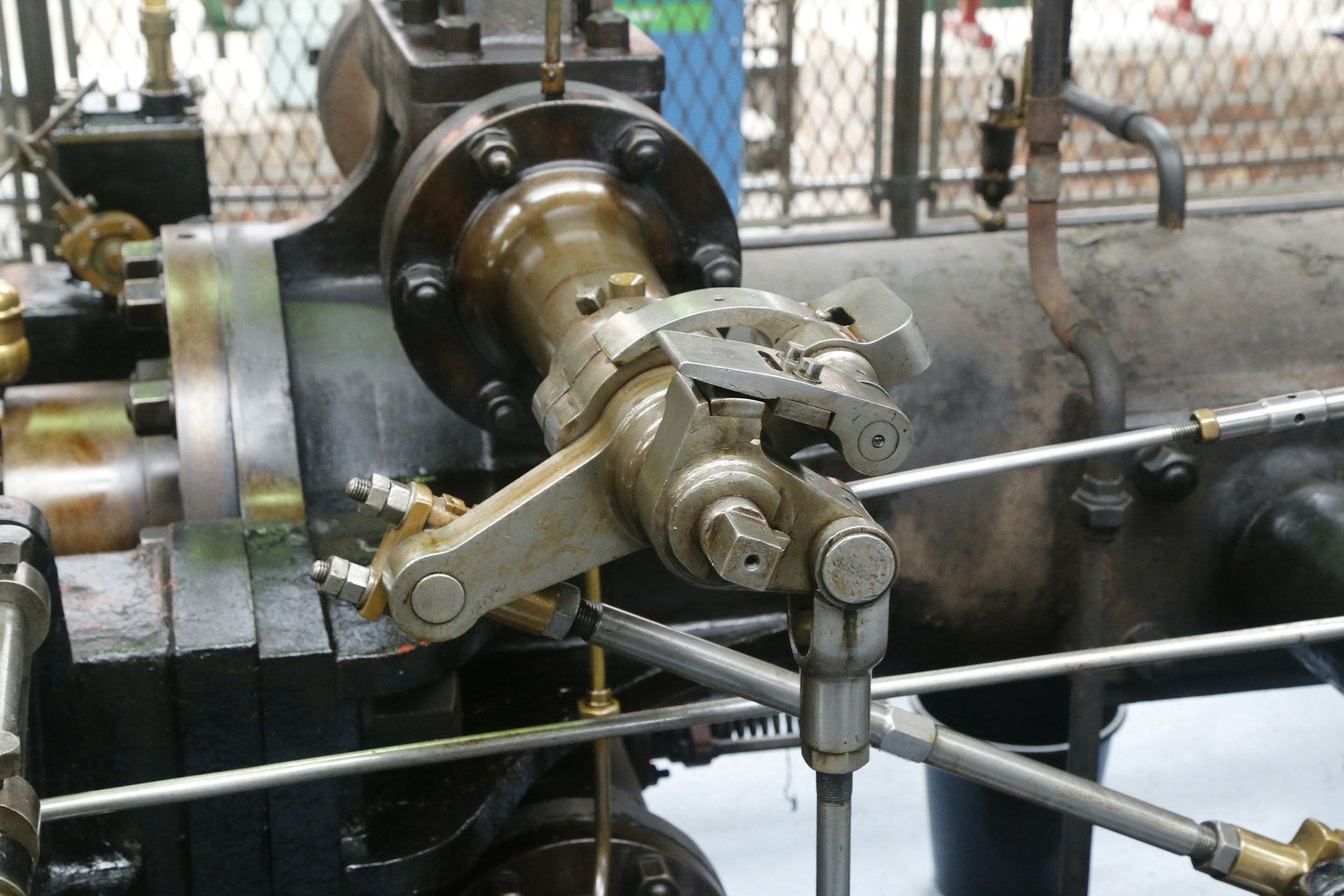

Fluid & Motion Systems

- Hydraulic and pneumatic system parts

- Pump internals, precision cylinders, pistons

- Wear-critical components in valves and regulators

- Seals, plungers, pump rotors/stators, turbocharger bushings

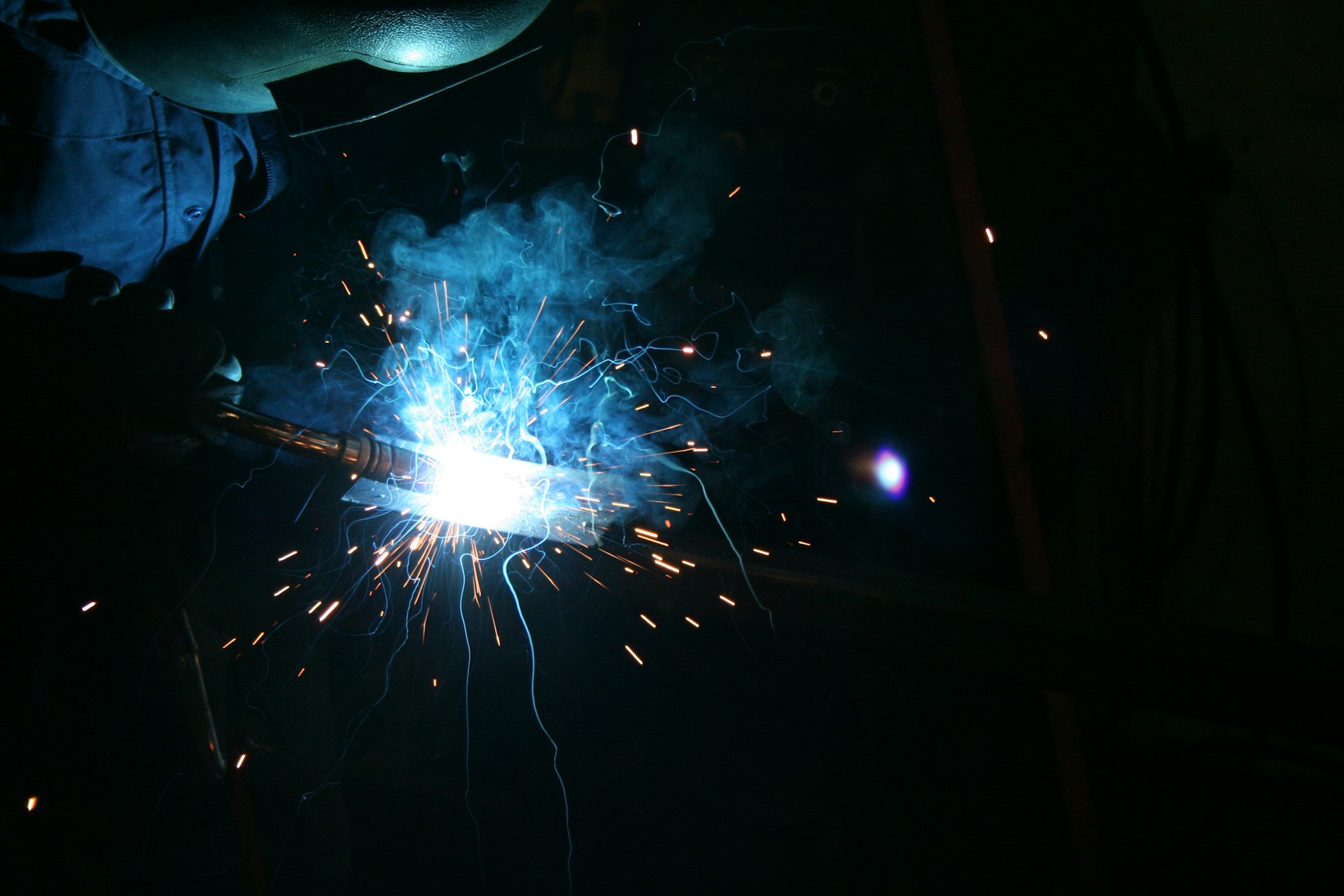

High-Performance & Specialized Applications

- Aerospace & defence components (gun barrels, landing gears, actuators)

- 3D-printed metal parts requiring stress relief

- Seam welding electrodes (e.g., Cu-Cr-Zr)

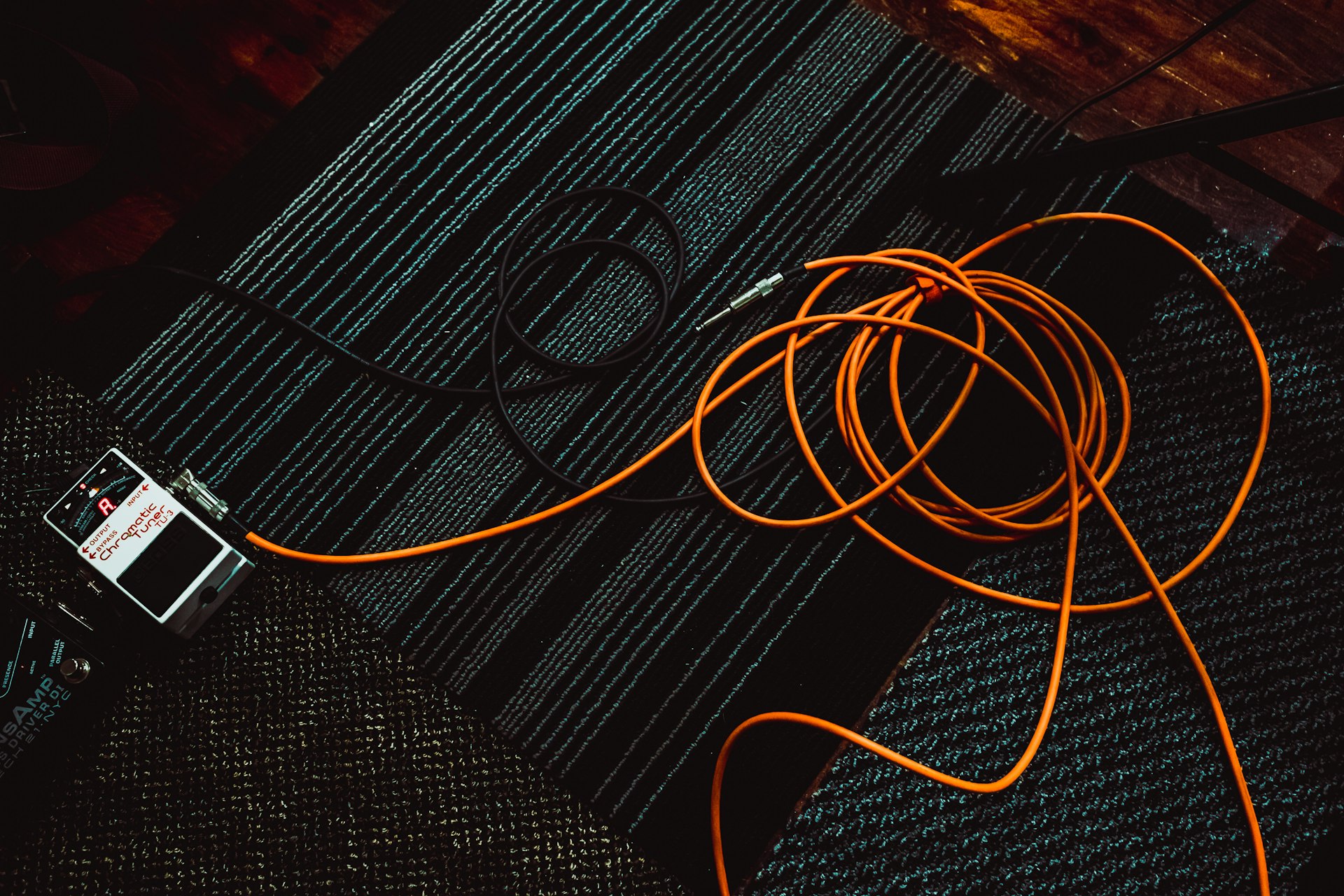

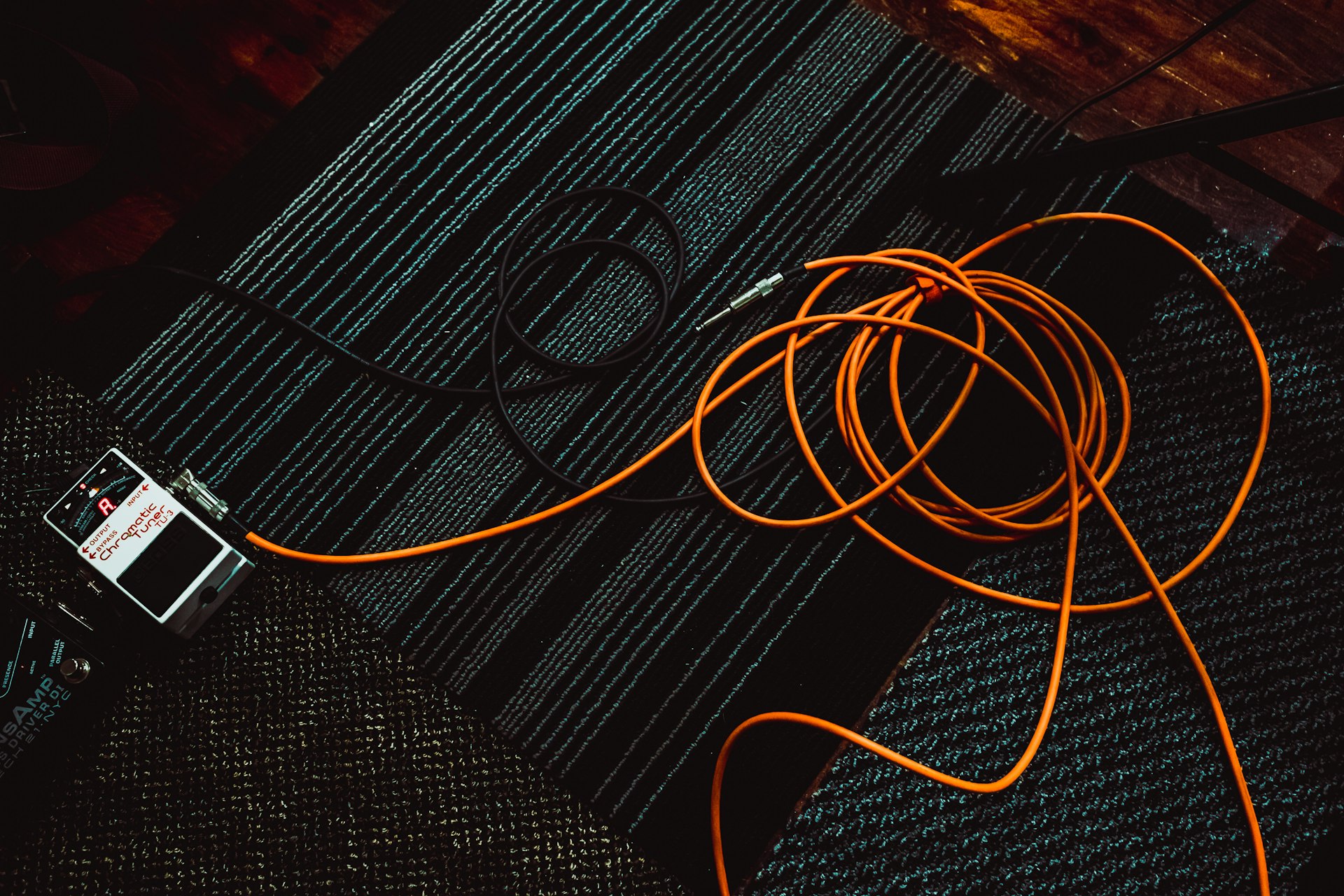

Precision Electronics & Audio

- Audio equipment parts (diaphragms, signal connectors)

- High-precision electronic tooling

- EMI shielding components & vibration-sensitive elements

Additional Applications

Beyond mainstream use, cryogenics is delivering strong results in several high-potential niche areas, such as:

- Medical & surgical tools – sharper, longer-lasting scalpels, orthopaedic drills, dental burs.

- Oil & gas equipment – wear-resistant downhole tools, valves, and pipeline couplings.

- Die-casting & foundry tooling – core pins and shot sleeves with higher thermal-fatigue life.

- Textile & packaging machinery – rotary knives and rollers that outlast standard parts.

- High-end consumer gear – custom knives, bike drivetrains, and sports blades with superior edge retention.

- Wood, glass & composite tooling – router bits and saw blades that stay sharp in abrasive media.

- Musical instruments & audio parts – cryo-treated reeds, connectors, and solder tips for cleaner tone.

- Renewable energy components – wind-turbine gears and solar-actuator parts with extended service life.

Cutting Tools

Cryogenic treatment enhances the hardness, wear resistance, and edge retention of both HSS and carbide cutting tools. This leads to longer tool life, better dimensional accuracy, and reduced burr formation—especially in high-volume or hardened-material machining.

Benefiting Components:

- Drills, end mills, slot cutters, reamers

- Gear hobs, shaper cutters, threading tools

- Carbide inserts, broaches, knurling tools

- Gun drill & centre drill

Key Benefits:

- 50–120% increase in tool life

- Cleaner cuts with less burr

- Reduced tool replacement and regrinding frequency

User Impact:

- Lower tooling costs

- Fewer machine stoppages

- Consistent part quality across production runs

Success Story 1 - Gear Hob Cutter Success Story 2 - Carbide Tooling

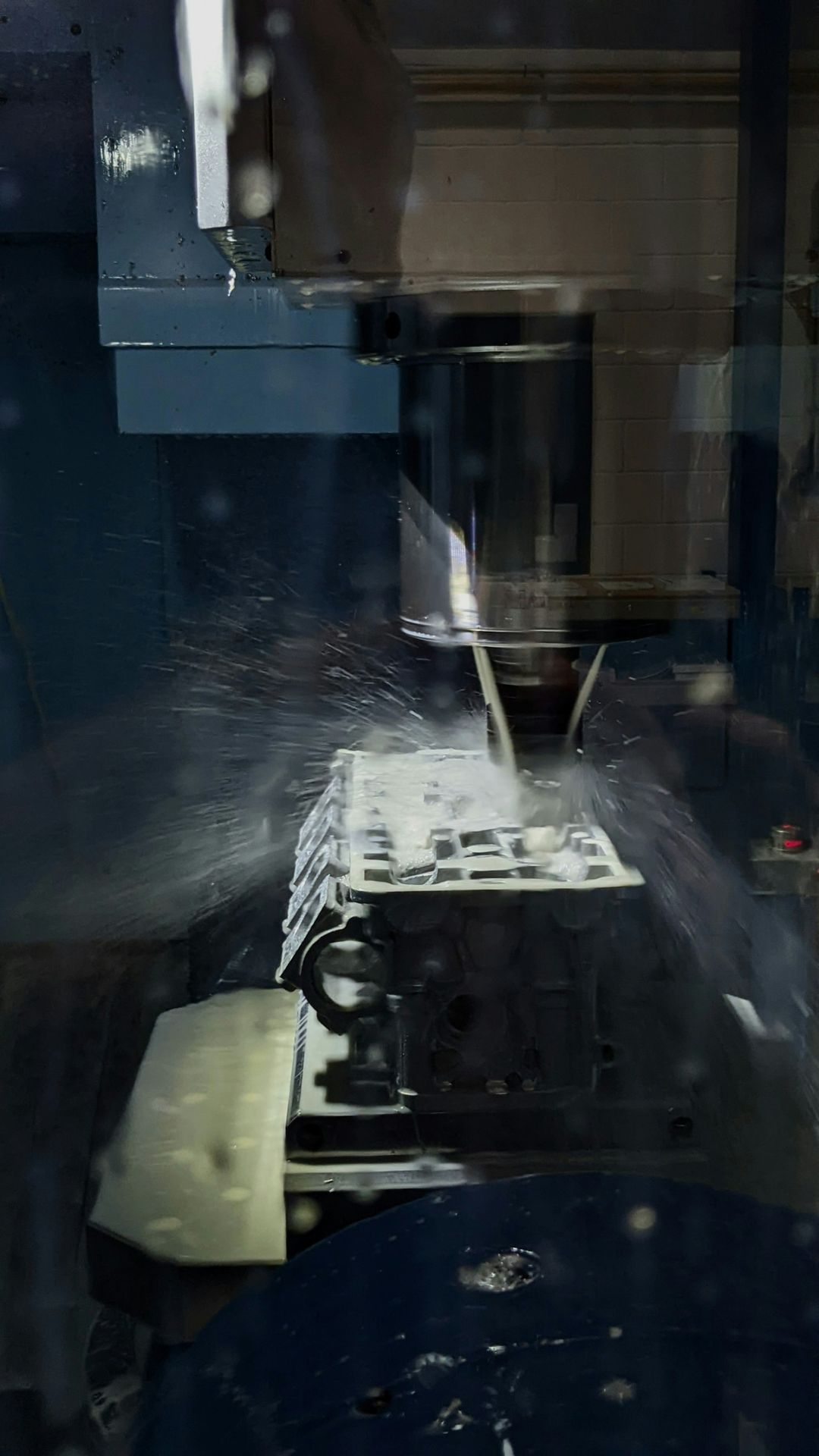

Forming & Stamping Tooling

Forming tools face continuous impact and frictional stress. Cryogenically treating these tools improves resistance to cracking, galling, and dimensional distortion, leading to longer die life and better component finish.

Benefiting Components:

- Blanking and trimming dies

- Stamping and coining tools

- Deep-draw and embossing punches

- Injection mould inserts, extrusion dies

Key Benefits:

- 1.5–3× increase in die life

- Reduced burrs and material pickup

- Better dimensional repeatability

User Impact:

- Less downtime for retooling

- Higher output per die set

- Lower part rejection and rework

Automotive & Off-Highway Components

Precision parts in automotive systems operate under cyclic loads, pressure, and temperature changes. Cryogenic treatment enhances wear resistance, fatigue life, and dimensional stability—critical for reliability and long-term performance.

Benefiting Components:

- Gears, shafts, crankshafts

- Brake rotors, clutch plates

- Fuel injectors, spools, bushings

- Cylinder liners, spark plug electrodes

Key Benefits:

- Extended component life under fatigue

- Better surface finish post-machining

- Reduced failure rates in hydraulic and mechanical systems

User Impact:

- Longer service intervals

- Lower warranty claims

- Improved performance consistency in field use

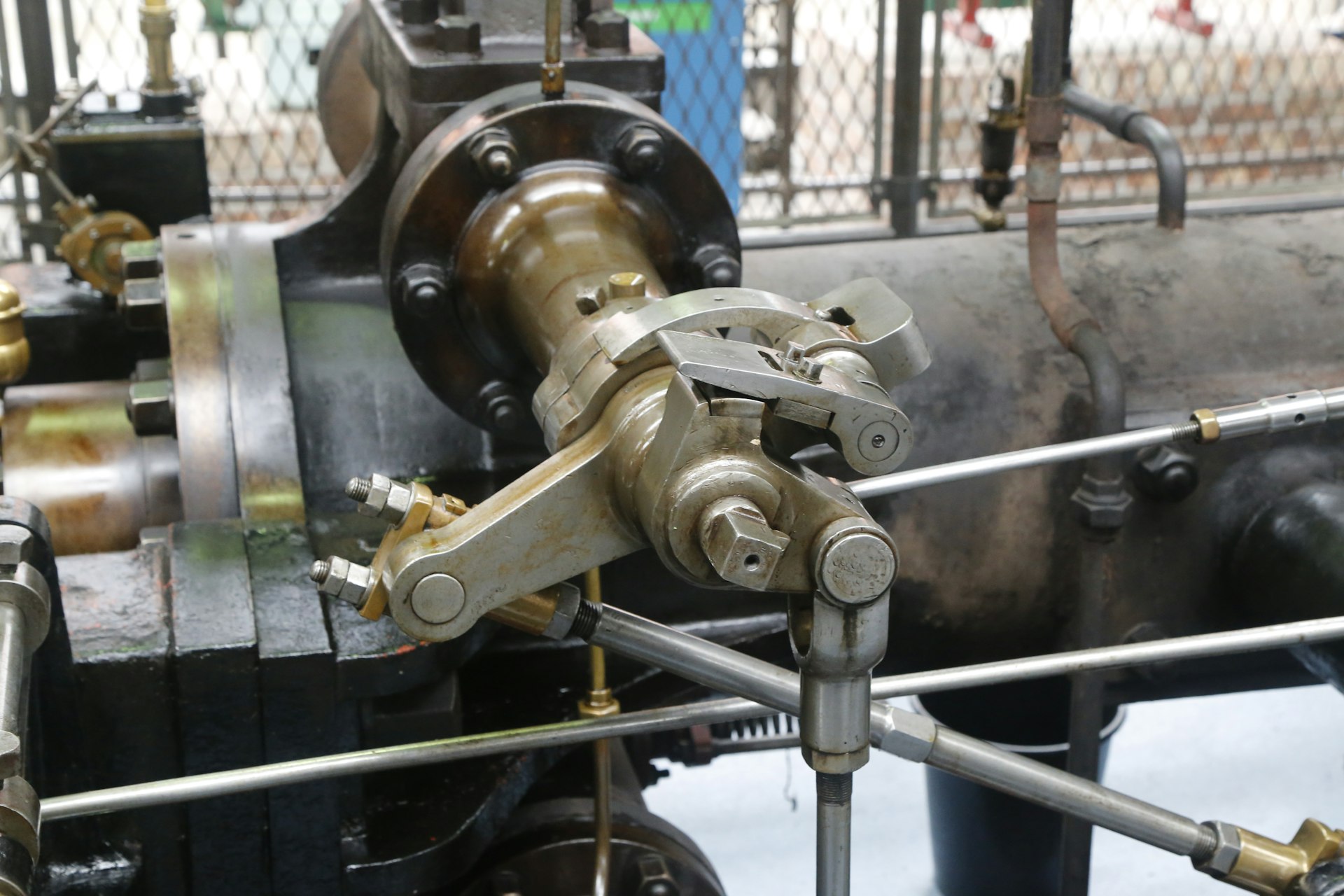

Fluid & Motion Systems

Hydraulic and pneumatic components require tight tolerances and wear control. DCT ensures stability after honing and reduces wear-related leakage or failure, especially in spools, valves, and pistons.

Benefiting Components:

- Hydraulic spools, valve seats

- Pump internals (plungers, rotors)

- Pneumatic cylinders, actuators

Key Benefits:

- Better dimensional stability post-finishing

- Reduced leakage and pressure drop

- Wear reduction on sliding/mating surfaces

User Impact:

- Improved system reliability

- Smoother operation under load

- Extended component and seal life

- Smoother wear profiles

High-Performance & Specialized Applications

In sectors like aerospace, 3D printing, welding, and defense, cryogenics supports performance-critical parts by enhancing thermal fatigue resistance, strength, and microstructural stability.

Benefiting Components:

- Aerospace actuators, landing gear pins

- Seam welding electrodes (CuCrZr discs)

- 3D-printed metal parts (structural, rotating)

- Defense weapon components (barrels, bolts)

Key Benefits:

- Stronger joints in welding

- Improved thermal stability

- Smoother wear profiles

User Impact:

- Higher reliability in mission-critical parts

- Consistent performance under extreme conditions

- Fewer early-life failures in precision components

Precision Electronics & Audio

While less known, cryogenics also benefits small, high-precision components in electronics and audio. It enhances conductivity, vibration damping, and structural stability, improving signal clarity and mechanical life.

Benefiting Components:

- Audio connectors, solder tips

- Signal contacts, switchgear elements

- Sensor housings, EMI shielding components

Key Benefits:

- Better signal consistency

- Longer lifespan of connectors

- Improved acoustic/vibrational response

User Impact:

- More reliable electronic performance

- Reduced failure in high-sensitivity applications

- Enhanced product experience in audio and instrumentation

Unlock more life, more precision, less downtime.

Get in touch to explore how cryogenics can work for you