About us

Pioneering Performance with Cryogenics since 2004

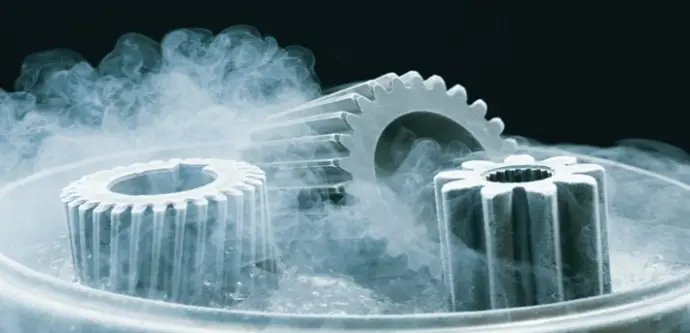

At BluePhase Cryogenics, we specialize in one thing—and we do it better than anyone else in India: Deep Dry Cryogenic Treatment (DDCT). Since 2004, we've been transforming the durability, reliability, and precision of metals used across industries—from tooling and automotive to aerospace, defense, audio, and beyond. We began with a US-patented technology and later adapted it to suit Indian industry requirements. Today, all our machines and processes are fully indigenized, proudly Make in India, and built to meet international quality standards.

Our proprietary cryogenic processes expose materials to ultra-low temperatures (as low as –190°C), unlocking powerful microstructural changes that drastically improve wear resistance, impact strength, dimensional stability, corrosion resistance, and more. Backed by decades of metallurgical research and field-proven outcomes, we help our clients extend product life, reduce failure rates, and optimize performance—without changing their base materials or designs.

The business impact is twofold—boosting both bottom line and top line. By extending tool life and minimizing unplanned downtimes, our clients realize significant reductions in operating and maintenance costs, directly improving profitability. Simultaneously, the enhanced material performance opens new possibilities: manufacturers can engineer high-performance, niche products that were previously impractical or uneconomical, thereby unlocking premium market segments and accelerating revenue growth. Whether you’re aiming to reduce waste or launch a differentiated offering, DDCT becomes a strategic enabler of both cost efficiency and competitive advantage.

Our operations began in Northern India in 2004, and today our plants span across Northern, Western, and Central India. With over two decades of experience, a strong footprint in India’s industrial and manufacturing ecosystem, and growing international collaborations, BluePhase stands as a trusted partner for those who seek performance without compromise.

We’re not just treating metals. We’re engineering longevity—and delivering measurable business value—into the core of your components.

Our Forays Beyond Cryogenics

We design and manufacture AA-class gear-cutting tools and steering components—gear hobs, spline and worm-wheel hobs, sprocket and timing-belt hobs, cylindrical and milling cutters—trusted by OEMs like Chevy, Ford, and Suzuki.

Powered by proprietary CAD/CAM software, multi-axis CNCs, and advanced PVD coatings, our integrated plant delivers export-ready tools that hold tighter tolerances, run longer, and cut production costs for transmission and power-train makers worldwide.

Meet our Leaders

Expert professionals driving our innovation

Atul Jain

Chief Executive Officer

MTech Metallurgy, IIT Kanpur, BE Metallurgy, PEC

As Founder and Chief Innovator, Atul leverages 18+ years in the automotive sector to lead BluePhase. His vision powers our cryogenic breakthroughs and our mission to engineer performance.

Aviruddh Jain

Chief Marketing Officer

MBA, IIM Bangalore, BE Manufacturing, BITS Pilani

Previously a strategy consultant, Aviruddh has now stepped into our 20+ year-old cryogenics business to unlock its next phase of growth and innovation

Looking for an edge to save costs & boost performance?

Our cryogenics specialists are here to assist you in understanding the benefits of deep cryogenic treatment and will provide you with the best advice for your wellness journey.